FAQs

Here are some of our customers' most Frequently Asked Questions. If your answer isn't here, visit our contact pageDelivery

At Wunda we know how important it is to get your order to you quickly. For areas in the UK mainland if you place your order before 6.00pm we can provide our standard delivery in the next 2 – 3 working days.

General FAQs

A Rapid Response® floor heating system produces heat in as little as 30 minutes because it has a level of controllability not seen before in under floor heating. Combined with our Home Heating Controls it can be turned on, off, up, down in individual areas of the home at the touch of a button on your smart phone, Ipad or laptop from wherever

The Rapid Response® heating system is a water-based floor heating system that uses low-temperature warm water to heat rooms evenly and quickly. Input temperatures can be as low as 45°C, using half the energy required to heat a radiator at 70-90°C.

This combined with the on demand nature of The Rapid Response® heating system, allows users to only heat the rooms they’re using, and not have to leave the heating on all the time like old traditional screed systems which took days to heat and cool.

The responsive use and lower energy requirements to run the Rapid Response® heating system make it a low carbon solution that’s compatible with current heating technology like gas/oil boilers; as well as working efficiently with alternative fuels of the future like hydrogen boilers and air & ground source heat pumps.

Rapid Response® on demand heat can reach desired temperatures in as little as 30 minutes.

This is thanks to all the work done in developing the Rapid Response® aluminium that’s used in both the board and pipe.

No, the spray contains no carcinogens and is CFC free.

Not at all! Rapid Response® boards are retro-fitted to the existing floor using our Wunda adhesive spray.

This saves time & cost in the installation as well as avoids any potential risks in digging up decades-old concrete substrates.

Rapid Response® is available in 16mm & 20mm profile boards.

The Rapid Response® boards are strong, high density boards composing of EPS and an Aluminum cover.

The boards have been tested at the University of Salford by their UKAS accredited product testing lab and got the following results back:

20mm of Rapid Response® has an R-value of 0.447 (+/- 2%)

16mm of Rapid Response® an R-value of 0.379 (+/- 2.8%)

In a new build it is expected that the property will be built in line with up to date building regulations.

In an older property that is successfully heated by radiators, the Rapid Response system will be more efficient and effective than radiators. Due to the insulative nature of EPS, little heat can be pulled down into a cold substrate. The system is not a replacement for insulation.

If your home is heated by radiators but has high heat loss, those areas of heat loss should be addressed regardless of your choice of heating system.

So in comparison to a system using just radiators, it’s superior in insulation and will heat more sufficiently with better energy efficiency.

Wunda only provides pipe which is 100% leak proof. By using a 5 layered pipe comprised of an EVOH barrier to prevent oxygen ingress and rusting the aluminium core as well as Pert for superior flexibility.

We also pressurise the pipe at the point of manufacture, so you know instantly before putting it in the floor whether the product’s been comprised in transit.

Since 2006 we’ve never had a leak. Ever.

Joist

Joist systems are perfect for upper floor properties.

Manifold

Ideally the manifold should be sited as centrally as possible. The manifold position will be marked on your pipe layout drawing. It can be hidden inside an existing cupboard or we can provide an elegant manifold cabinet.

A manifold allows water to pass through its hollow core, this water then is distributed to the relevant destination (loop/zone). It will generally incorporate a pump and mixing valve to circulate the water around the loops & regulate the water temperature to a point that is suited for the floor finish

Pipe

We supply pipe layout drawings which detail where every loop of pipe is laid and the length of each loop. You or your installer can’t go wrong!

Water based floor heating is laid using continuous loops of pipe in the floor, meaning the only joins are at the manifold – not under the floor.

Pipe that is pressure sealed at the point of manufacture like Wunda’s emits a hissing escape of air when the seal is cut on site. This allows the installer to safely guarantee the pipe is 100% leak proof before install and will give you peace of mind too.

Rapid Response®

It’s a common misconception that underfloor heating is a luxury accessory to keep feet warm. In fact, it’s the most efficient heating system available! By replacing your radiators with Wunda water-based underfloor heating, you can save space, increase comfort, and make your home net zero ready.

To learn more about our water-based underfloor heating systems, please visit our website at Wunda Group.

The insulative properties of our Rapid Response® boards have been tested at the University of Salford’s UKAS accredited testing lab. The results are as follows:

- 20mm of Rapid Response® has an R-value of 0.447 (+/- 2%).

- 16mm of Rapid Response® has an R-value of 0.379 (+/- 2.8%).

Please note that while the EPS material is insulative, it is not a replacement for insulation. In a new build, the property is expected to be built in line with up-to-date building regulations.

If you have an older property that is successfully heated by radiators, the Rapid Response system will heat more efficiently and effectively than radiators. However, if your home is unsuccessfully heated by radiators due to high heat loss, the heat loss should be addressed regardless of your choice of heating system.

How much height does this add to the room?

Our Rapid Response panels come in two sizes: 16mm and 20mm (about the size of a 20 pence piece). To calculate the total build-up height, add this to the height of any necessary decoupling layer such as a 5mm screed (tiling, LVT) along with your floor finish.

Please note that the choice between the 16mm and 20mm panel has little to no effect on heat output but will affect price. Systems using the 16mm panel are more expensive than those using the 20mm panel, due to an increased amount of pipe being necessary.

The Rapid Response® system should be laid on as flat a surface as possible. The polystyrene boards are fairly forgiving, but if there are any dips, holes, or undulations in the floor, we recommend using a levelling screed to deal with them. The floor should be dry and free of dust, oil, or other contaminants to ensure that the adhesive sticks properly.

For more information about floor preparation, check out this blog post: How To Install Underfloor Heating On Concrete Floor – Wunda Group.

Our Rapid Response® system is compatible with most floor finishes, including carpet and underlay (up to 2.5 tog), wood, LVT, laminate, concrete, and tiles. Wunda Rapid Response® high-density boards also support heavier floor finishes such as marble and stone tiles. These boards are approved by leading tile adhesive manufacturers to be laid directly on top without the need for an intermediary layer. This helps to reduce system cost, build-up height, and decrease installation time.

For those opting for a wood or vinyl finish, we supply floor probes to protect the floor finish. Please note that wood products such as Maple and Beech are not compatible.

For more information on each floor finish, please visit our website at Underfloor Heating for Different Floor Types | Wunda Group.

To ensure that our rapid response system works optimally, we recommend installing it on a fixed floor made of wood, concrete, tile, or stone. This will prevent any movement and ensure that the system functions smoothly. Please note that the system should not be installed on top of any floating floor, and any such floor finish should be removed first. This applies to carpet, LVT, and laminate flooring. If you wish to install the system on top of tiles, please ensure that the floor is dry and free of any contaminants.

Some customers prefer to remove any fixed floor finishes to keep the build-up height as low as possible. We recommend that any existing old asbestos flooring tiles be professionally removed before laying a new floor on top. This will ensure the safety of everyone involved.

Water based underfloor heating does require some maintenance. In comparison to radiators water underfloor heating needs very little maintenance and the maintenance it does need is easier to carry out, as the system is maintained from one central point – the manifold.

The maintenance follows a similar to process to central heating with radiators. Ensure there’s no air in the system by releasing at the manifold and turn on after summer before the depths of winter to check all is running smoothly.

A Rapid Response® floor heating system produces heat in as little as 30 minutes because it has a level of controllability not seen before in under floor heating. Combined with our Home Heating Controls it can be turned on, off, up, down in individual areas of the home at the touch of a button on your smart phone, Ipad or laptop from wherever

The Rapid Response® heating system is a water-based floor heating system that uses low-temperature warm water to heat rooms evenly and quickly. Input temperatures can be as low as 45°C, using half the energy required to heat a radiator at 70-90°C.

This combined with the on demand nature of The Rapid Response® heating system, allows users to only heat the rooms they’re using, and not have to leave the heating on all the time like old traditional screed systems which took days to heat and cool.

The responsive use and lower energy requirements to run the Rapid Response® heating system make it a low carbon solution that’s compatible with current heating technology like gas/oil boilers; as well as working efficiently with alternative fuels of the future like hydrogen boilers and air & ground source heat pumps.

Rapid Response® on demand heat can reach desired temperatures in as little as 30 minutes.

This is thanks to all the work done in developing the Rapid Response® aluminium that’s used in both the board and pipe.

No, the spray contains no carcinogens and is CFC free.

Not at all! Rapid Response® boards are retro-fitted to the existing floor using our Wunda adhesive spray.

This saves time & cost in the installation as well as avoids any potential risks in digging up decades-old concrete substrates.

Rapid Response® is available in 16mm & 20mm profile boards.

The Rapid Response® boards are strong, high density boards composing of EPS and an Aluminum cover.

The boards have been tested at the University of Salford by their UKAS accredited product testing lab and got the following results back:

20mm of Rapid Response® has an R-value of 0.447 (+/- 2%)

16mm of Rapid Response® an R-value of 0.379 (+/- 2.8%)

In a new build it is expected that the property will be built in line with up to date building regulations.

In an older property that is successfully heated by radiators, the Rapid Response system will be more efficient and effective than radiators. Due to the insulative nature of EPS, little heat can be pulled down into a cold substrate. The system is not a replacement for insulation.

If your home is heated by radiators but has high heat loss, those areas of heat loss should be addressed regardless of your choice of heating system.

So in comparison to a system using just radiators, it’s superior in insulation and will heat more sufficiently with better energy efficiency.

Wunda only provides pipe which is 100% leak proof. By using a 5 layered pipe comprised of an EVOH barrier to prevent oxygen ingress and rusting the aluminium core as well as Pert for superior flexibility.

We also pressurise the pipe at the point of manufacture, so you know instantly before putting it in the floor whether the product’s been comprised in transit.

Since 2006 we’ve never had a leak. Ever.

Thanks to retro-fit systems like Rapid Response® 100m2 can be laid in just two days using quick drying Wunda Spray adhesive. It’s no longer a case of digging all your floors up, simply take up your carpet, prepare your sub-floor and lay a retro-fit system.

Retro-fit options like Rapid Response® floor heating boards are laid directly under your floor finish and when covered with the optimum thickness of 200 micron aluminium they provide Rapid Response® warmth reaching desired temperatures in 30 minutes and ensuring an even heat across the entire floor – this makes floor heating just as controllable as radiators.

Old fashioned floor heating laid deep in concrete could take up to 72 hours to heat up or cool down.

No! That’s the old fashioned way. Modern floor heating such as Rapid Response® floor heating comes in moulded, easy to shape, high density polystyrene aluminium coated boards made from eco-friendly EPS (as opposed to harmful XPS). The board is bonded to the existing floor before running the pipes in and through to the manifold. The desired floor finish is laid on top – no digging, no mess!

Screed

Screed systems are traditionally used in new build projects. Screed systems require the floor heating pipes to be fixed to the sub floor insulation layer prior to being encased in a layer of concrete or chemical screed. The warm water in the pipes heat up the concrete (screed) which acts as a thermal store and radiates it into the living space. This process can take a few hours to both heat up and cool down and is less controllable than overfloor systems.

Thermostat

A hardwired thermostat is powered by a 240v mains supply, a physical wire (3 core plus earth) Is used to trigger the appropriate output, to a wiring centre if one of many thermostats, or directly to the output if a single zone.

A wireless thermostat communicates to a receiver using radio frequency (RF) (either single channel or multi zone depending on the number of thermostats you have) meaning no need for wiring between the thermostat and manifold. Our RF thermostats cannot take a floor limitation probe so other steps are required to protect temperature sensitive floor finishes.

Underfloor heating

Water based underfloor heating does require some maintenance. In comparison to radiators water underfloor heating needs very little maintenance and the maintenance it does need is easier to carry out, as the system is maintained from one central point – the manifold.

The maintenance follows a similar to process to central heating with radiators. Ensure there’s no air in the system by releasing at the manifold and turn on after summer before the depths of winter to check all is running smoothly.

The Rapid Response® heating system is a water-based floor heating system that uses low-temperature warm water to heat rooms evenly and quickly. Input temperatures can be as low as 45°C, using half the energy required to heat a radiator at 70-90°C.

This combined with the on demand nature of The Rapid Response® heating system, allows users to only heat the rooms they’re using, and not have to leave the heating on all the time like old traditional screed systems which took days to heat and cool.

The responsive use and lower energy requirements to run the Rapid Response® heating system make it a low carbon solution that’s compatible with current heating technology like gas/oil boilers; as well as working efficiently with alternative fuels of the future like hydrogen boilers and air & ground source heat pumps.

Our experts are more than happy to offer FREE advice before, during and after your system has been installed – just call or email us. Rest assured though that all of our components carry long guarantees and are backed up with a £10M Product Liability insurance with AXA.

Not at all! Wunda’s floor heating systems have been developed with the confident DIYer in mind, being able to lay the pipe and panels, leaving final commissioning to the professionals. If you’re extending or renovating, even simpler would be to make use of the builders already on-site and get them to install it for you.

Floor heating and radiators happily work in conjunction with one another, to achieve this you will need to ‘T’ off from your boiler primaries, so one set of flow and return will go towards your radiators and the other to your floor heating system. Your heat source (boiler / heat pump) will still be producing hot water for your radiators, the same temperature water will be blended at the UFH manifold by a mixing valve. So while the heat source is still producing ‘hot water’ the UFH system ensures that you need less of it – saving you energy and money.

Any competent plumber can easily do the work for you to commission your heat source (boiler / heat pump) to both radiators (commonly upstairs) and underfloor heating (commonly on the ground floor).

Electric has much higher running costs in comparison to water based systems making it suitable for smaller areas such as en suites but not for larger living areas and whole homes. For open plan kitchen and family areas, water based systems are more economic costing up to 65% less to run than electric.

Most floor finishes can be used with floor heating, Wunda developed Rapid Response®, high density boards to support heavier floor finishes such as marble and stone tiles. These boards are independently approved by leading tile adhesive manufacturers to be laid directly on top without the need for an intermediary layer that other, less dense, boards may require, this helps to reduce system cost, build up height and lower install time.

If you’re opting for a wood floor be sure to install a floor probe to protect the integrity of the wood from fluctuating temperatures and do check with your flooring supplier as some products such as Beech wood may not be compatible.

No, most users of floor heating install on the ground floor and combine the system with radiators upstairs – but you can install throughout the whole house if you wish.

Absolutely, water based floor heating runs at lower temperatures, normally 35°C – 55°C, which is about half of what radiators run at. Water based floor heating is future proof and can be run from any heat source including heat pumps.

Warm water is pumped from the heat source to the manifold. If the floor heating requires warm water, the thermostatic valve will open allowing heated water into the manifold. From the manifold, heated water is pumped around the floor heating pipes, returning to the manifold and then either released back to the boiler/heat source via the boiler return valve for re-heating or blended back into the floor loop via a one-way valve. When all rooms reach desired temperatures, the room thermostats will signal to the actuators and pump to shut down, this in turn stops heated water circulating through the floor.

Water Underfloor Heating FAQ

Electric has much higher running costs in comparison to water based systems making it suitable for smaller areas such as en suites but not for larger living areas and whole homes. For open plan kitchen and family areas, water based systems are more economic costing up to 65% less to run than electric.

Learn more about the pros and cons of UFH

An underfloor heating system can be an ideal and cost-effective way of keeping your home warm. It can be easily installed yet does require a fair amount of preparation and time.

Even before installing an underfloor heating system, there are other ways to reduce heat loss in your home which can prove easy and budget-friendly.

Many people have the perception that underfloor heating is incredibly difficult to install. Involving huge pipes with lots of digging, often leading to them thinking it will be a costly and stressful process. However, with a Wunda Rapid Response® system, this could not be further from the truth.

There’s no digging up floors and installation is easy and relatively hassle free. 75m2 could be laid over a weekend by competent DIYers ready for your professionals to hook up to your heat source.

Find out more about underfloor heating cost.

Warm water is pumped from the heat source to the manifold. If the floor heating requires warm water, the thermostatic valve will open allowing heated water into the manifold. From the manifold, heated water is pumped around the floor heating pipes, returning to the manifold and then either released back to the boiler/heat source via the boiler return valve for re-heating or blended back into the floor loop via a one-way valve. When all rooms reach desired temperatures, the room thermostats will signal to the actuators and pump to shut down, this in turn stops heated water circulating through the floor.

Retrofitting underfloor heating can be a relatively easy process without the need to dig up the floors throughout your house. Wunda’s easy to install system comes with so many benefits, it warms up just as quickly as radiators and runs at a lower flow temperature which uses much less energy.

UFH circulates warm water through the plastic pipes to effectively heat up the floor first and allow for a warm living area with a cool ceiling. The water’s temperature can be between 35 and 55°C which is regulated by a mixing valve at the manifold.

Find the Ideal Temperature for Underfloor Heating in your home

Tile and natural stone floors work perfectly with underfloor heating as they are natural conductors. One thing to remember with these floor finishes is the thicker they are, the longer your response time will be and the longer the floor finish itself will hold the heat and take to cool down.

Learn more about UFH and floor coverings.

Underfloor heating systems will cost users around 25% less than radiators to run on average and 60% less than electric floor heating systems. When installing a Wunda Rapid Response® system which uses smart controls and zoning the savings can be up to 50%.

Learn more about underfloor heating efficiency

Wunda’s easy to install system comes with so many benefits, it warms up just as quickly as radiators and runs at a lower flow temperature which uses much less energy. You’ll be able to heat each room separately, and your home will be far more comfortable with heat rising from the floor and heating the whole room.

WundaSmart

We do not provide installation of WundaSmart.

For the smoothest installation, we recommend hiring a professional electrician or heating engineer to fit your WundaSmart HubSwitch. The WundaSmart HubSwitch installation is as easy as installing any heating programmer / controller or time clock.

HubSwitch Installation

Installation can be as simple as replacing your existing central thermostat or time clock.

Radiator/Thermostat Installation

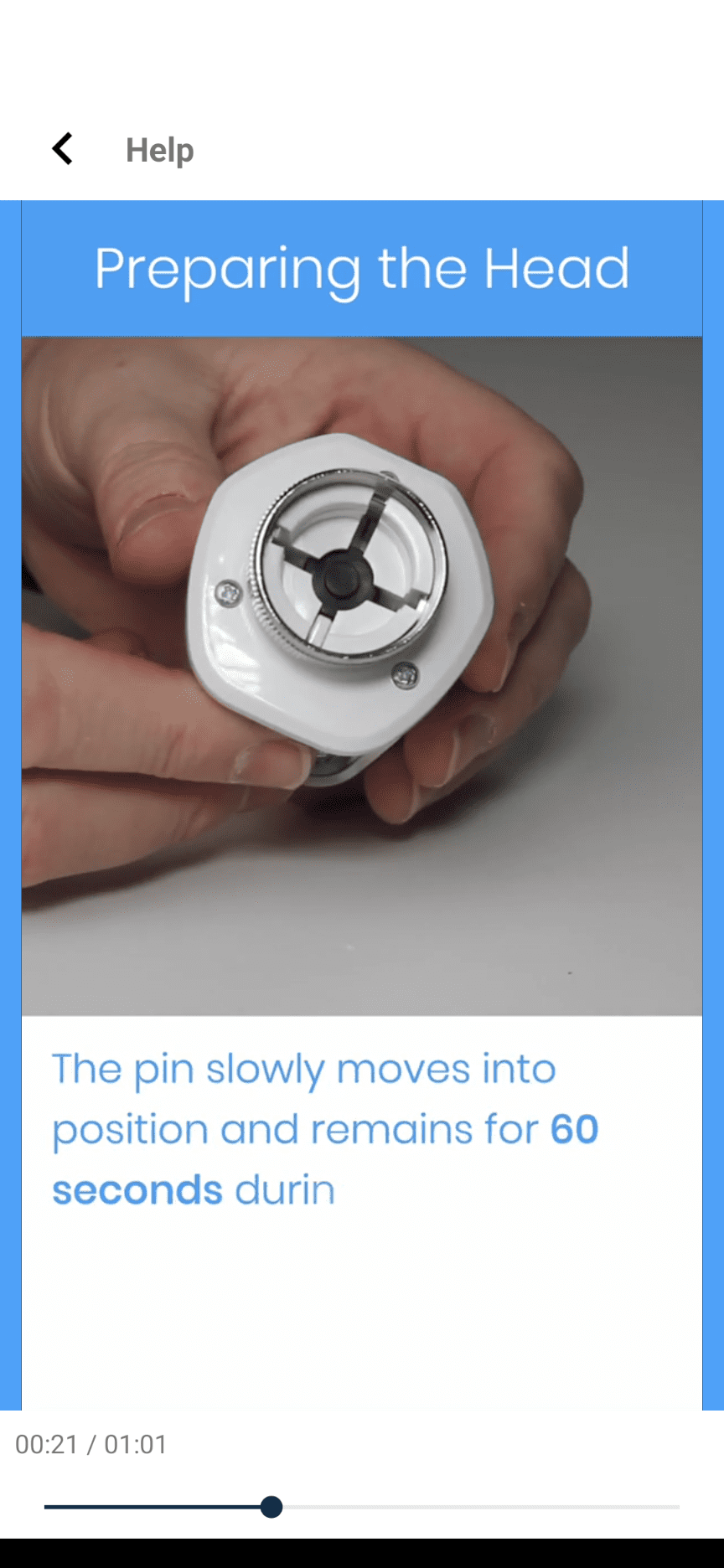

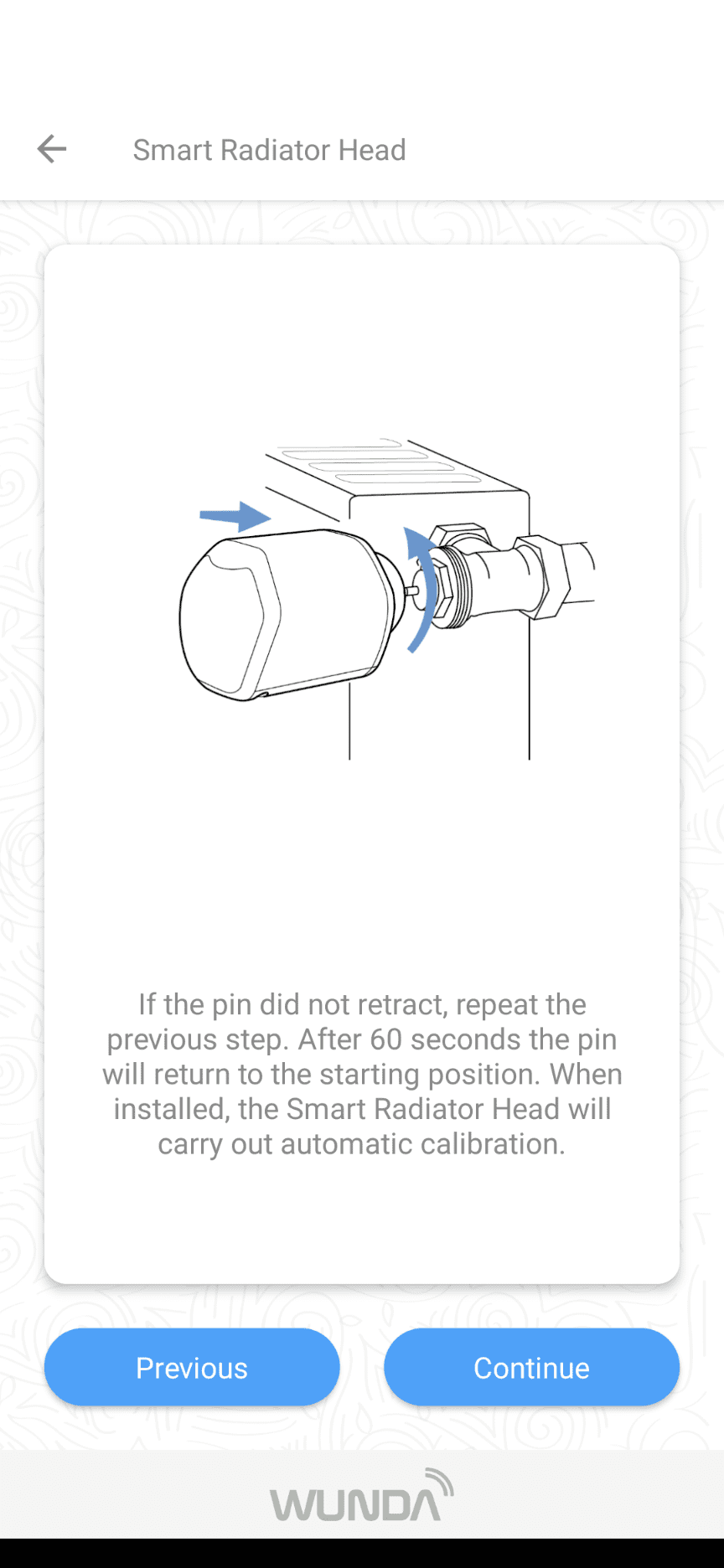

Quick and simple to do, the App guides you through the whole process.

Each room can be set up easily and the devices can be paired in minutes.